How cashew shelling machine works?

There are three types of cashew cracking machines. And you may be curious about how cashew shelling machine works.

- Manual cashew shelling machine

- Semi-automatic cashew sheller

- Automatic cashew cracking machine

The following paragraphs will describe how to use these three types of machines.

Manual cashew shelling machine

The machine consists of two blades. Put raw cashew nuts between the blades. Start cracking with hands and feet to drive the blades closer, squeezing the cashew nuts. And the shells are split. With this sheller, a person can produce 15-20 kilograms every eight hours. And the integrity rate of cashew kernels can reach 90%. The machine has a high rate of opening shells at one time, a high rate of whole cashew kernels, simple operation by workers, and high production efficiency.

Semi-automatic cashew sheller

This cracking machine also breaks cashew with blades. Compared with the manual machine, one can cut six cashew nuts or more at the same time. Put cashew nuts into the holes of the operating table, and step the foot pedal to drive the long blade down, achieving the cracking operation. This mode of operation is more efficient and the cashew buts are complete.

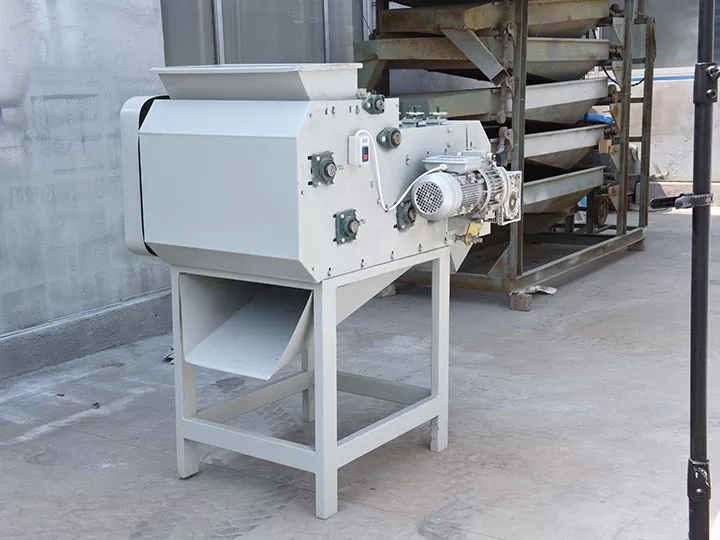

Automatic cashew cracking machine

The automatic cashew breaking machine includes the feeding hooper, the transfer belt, and the shelling part. Pour the cashew nuts that need to be shelled into the feeding hooper. As the machine starts, the cashew nuts are transported to the grooves by the conveyor belt, and then the shells are broken as the machine rotates. Compared with the other two machines, the fully automatic operation is simpler to operate, the efficiency is the highest. And it saves manpower.

Customers could choose the type of cashew shelling machine according to their demands. And if you want to know other details of the machines, leave you messages.