Small and Large Cashew Nut Processing Machines (100kg-1000kg/h)

Cashew Processing Unit | Cashew Processing Plant

Brand: Taizy

Capacity: 100-1000kg/h

Main machine: cashew shelling machine, cashew peeling machine, cashew dryer, cashew roasting machine

Material: stainless steel

Mode of transportation: sea or air

Warranty: 1 year

The fully automatic cashew nut processing machines are designed for plants to produce cashews on a small or large scale. It includes grading, shelling, separating, peeling, and other machines. In Taizy machinery, there are 300kg small and 1000kg large cashew nut processing plants for sale.

Therefore, customers could choose the machine that they want, or we can customize a production line according to their output.

It is worth mentioning that our fully automatic cashew nut processing machines are highly efficient. All the cashew processing machines could be used as a single one or matched with hoists to form a full cashew nut processing production line.

The Machinery Required for Cashew Processing

In cashew nut processing factories, we often see the following models used in the cashew nut processing line. We will give you a detailed description of these machines.

Raw Cashew Nut Grading Machine

To ensure top-quality output, the cashews begin at our automatic grading machine. Its innovative design combines a perfectly calibrated screen angle with a matched vibration frequency. This allows the nuts to flow and roll smoothly without lodging, leading to precise size separation. Preparing the nuts this way is critical for maximizing the whole-kernel rate in the shelling process.

We can also customize the machine for the specific number of grades you require.

Cashew Nut Cooker

The graded cashews then enter our stainless-steel cashew cooking steamer, where a 30-minute steam cycle softens their shells for perfect shelling. This essential process protects the valuable kernel from damage. Our machines are highly adaptable, offering natural gas, steam, or electric heating options, and come in multiple sizes (12, 24, or 36-tray models) to scale with your business needs.

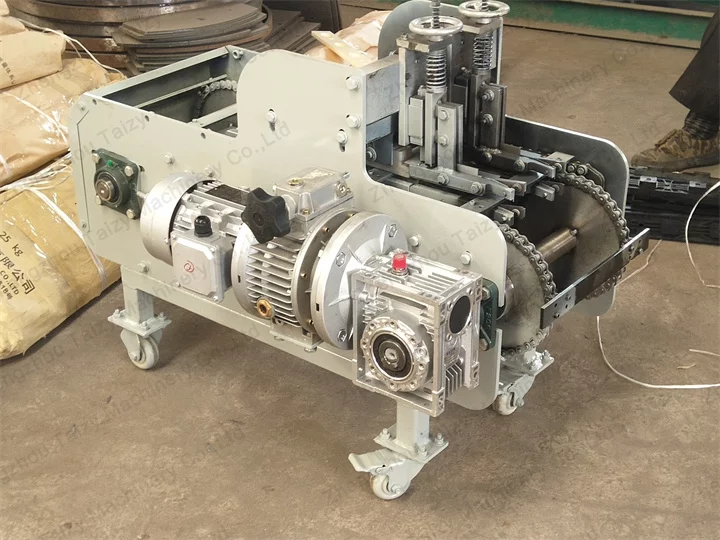

Cashew Nut Shelling and Cracking Machine

After steaming and natural air-drying, proceed with shelling the cashews. There are three types of cashew shellers: automatic cashew sheller machines, semi-automatic crackers, and manual shellers.

The heart of the cashew nut processing machines, ourautomatic cashew shelling machine is engineered for high-speed, efficient production. It achieves an exceptional shelling rate of over 95%, ensuring maximum yield from your raw materials.

While operating at high capacity, the mechanism is designed to be gentle, delivering a whole kernel rate of approximately 85%. To perfectly match your business scale, we offer models with 2, 4, 6, or 8 shelling blades, providing a customizable solution for your throughput needs. You can use the automatic cashew shelling machine in a large-scale cashew processing line.

| Model | Capacity | Size | Shell rate | Whole kernel rate | Motor power | Voltage |

| SL-20 | 17-20kg/h | 0.6*0.8*1.7m | 95% | 85% | 0.75kw | 200v/380v |

| SL-30 | 35-45kg/h | 1.2*1.6*1.7m | 95% | 85% | 1.1kw | 200v/380v |

A semi-automatic cashew cracking machine could shell 6 cashew nuts at one time. Workers must put cashew nuts into the holes and step pedals to crack shells.

The machine should be operated with caution. It is more suitable for use with semi-automatic cashew nut processing machines.

And for manual cashew sheller, workers put one cashew nut into the hole, and step the pedal to the shell nuts. This is suitable for some areas with lower labor costs for they could hire more workers to produce nuts.

Cashew Shell Kernel Separator

After shelling, the cashew mixture is fed into this motor-driven cashew shell separating machine, where multi-deck meshes separate kernels, shells, and fines by size. Made of food-grade stainless steel, it runs stably and is easy to clean. The screen length and mesh configuration can be customized according to capacity requirements, and it is suitable for cashews as well as other nuts such as almonds and peanuts. This unit ensures cleaner material for the drying and peeling stage while reducing kernel breakage and improving line efficiency.

Cashew Drying Machine

This cashew dryer machine is used to dry cashew kernels, so it is easier to blow off the skins in the following peeling machine. This drying machine is a tray dryer.

The size could be made to match the customer’s output. It could use electricity and gas as heating sources. And the machine could also dry other nuts and food.

Cashew Peeling Machine

Unlock superior efficiency with our pneumatic peeling machine, processing up to 200kg/h of cashews, garlic, and more. Its advanced air-vortex technology ensures a 95%+ peeling rate while keeping kernels perfectly intact. Built from durable, food-grade stainless steel, this versatile machine is fully customizable to meet your specific output needs and maximize your production line’s profitability.

Cashew Kernel Classifying Machine

Maximize your product value with our precision cashew kernel size sorter. This unit automatically and efficiently sorts kernels into 3-5 distinct sizes, ensuring consistent product specifications for higher market appeal. Constructed entirely from food-grade stainless steel, it operates smoothly with a gentle mechanism that preserves kernel integrity. This grader is the ideal solution for standardizing your output and boosting profitability.

Cashew Roasting Machine (Optional)

This cashew roaster machine is mainly used to roast cashew nuts, chestnuts, walnuts, peanuts, almonds, swallowing beans, coffee beans, melon seeds, and other granular materials.

According to customer requirements, we can design to use gas, diesel, and electricity as heating sources. When the machine is working, the rotating drum structure allows the cashews to be heated more evenly.

Vacuum Packaging Machine

As the final step in your cashew production line, our recessed-chamber vacuum packaging machine is essential for preserving freshness and extending shelf life. It creates a perfect airtight seal to protect your cashews from oxidation and moisture, locking in their signature flavor and crunch.

Specifically engineered for bulk packaging, its dual-chamber design allows for continuous, high-speed operation to maximize throughput. Built from heavy-duty stainless steel, this machine delivers the hygienic, reliable performance needed to secure your product quality and enhance market value.

Highlights of Taizy’s Automatic Cashew Nut Processing Machine

- Durable quality

The automatic cashew nut processing machine is made from high-quality stainless steel material, which enables a long service life.

- High efficiency

The production line could process large-scale cashew nuts in a short time. You can process 1,000 kg of cashews per hour. And the final perfect cashew kernels can reach 98%.

- Multiple choice

The cashew nut processing plant can be customized according to the customer’s production requirements. Whether you are looking for a small cashew nut processing machine or a large cashew processing machine, we can provide you with the perfect solution.

- Low labor cost

The entire cashew processing production line can be easily operated by only 3-4 people.

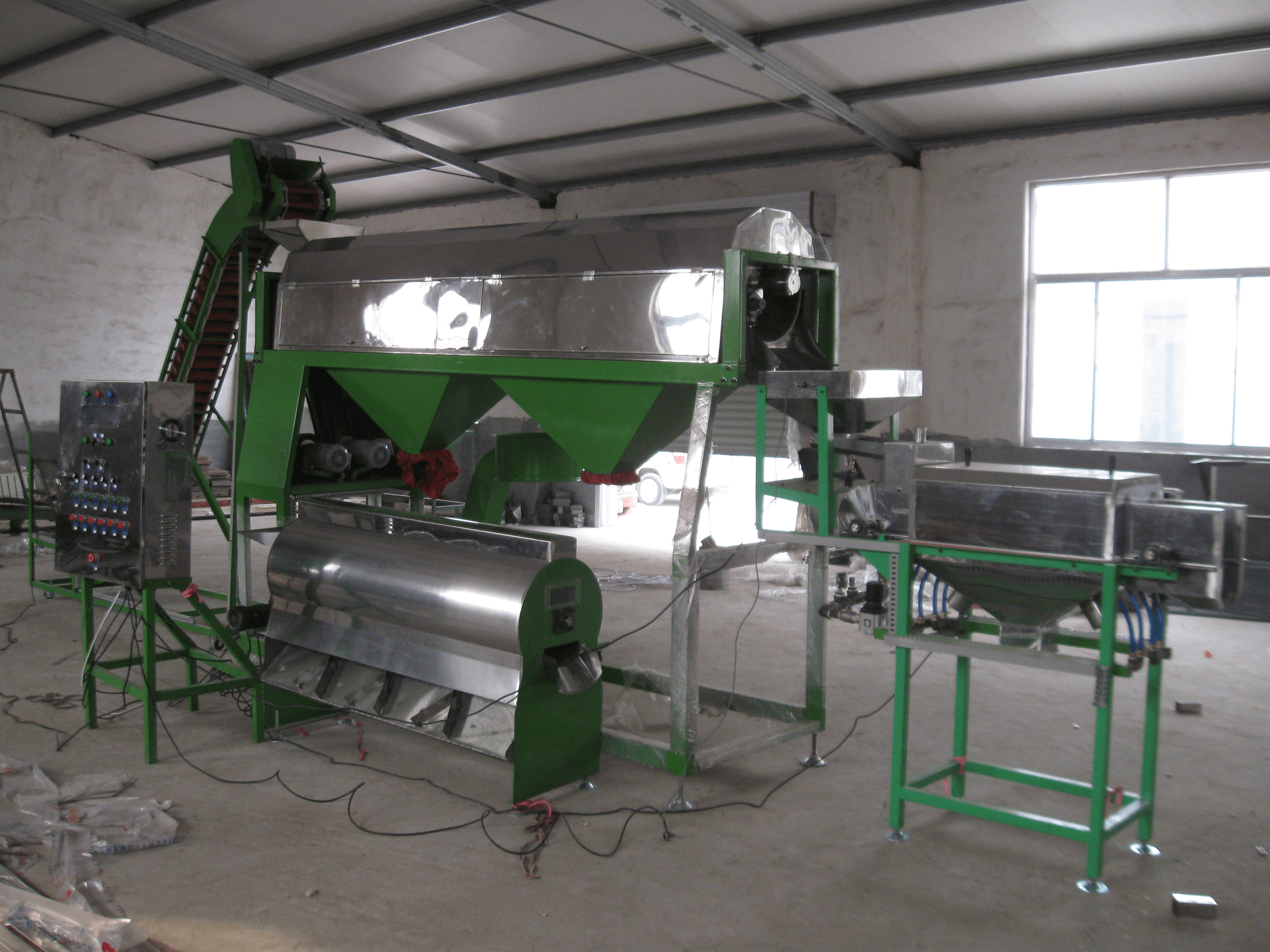

Large Scale Cashew Nut Processing Plant (1000kg/h)

If you want to build a cashew processing plant with an output of 1,000 kg/h, you will need elevators and conveyors in addition to the basic cashew processing machines.

Therefore, the 1000kg fully automatic cashew nut processing machine includes cleaning, grading, cooking, shelling, separating, drying, peeling, roasting, hoisting, and conveying machines.

If you want to know the model and specific configuration of each machine, please feel free to contact us.

Small Cashew Nut Peeling Processing Plant (100-300kg/h)

The configuration of a small cashew processing line is similar to that of a large cashew processing line. The difference is that you can choose a semi-automatic machine instead of a fully automatic machine.

For example, you can choose a semi-automatic cashew shelling machine. In addition, you can also use manual labor instead of conveyor belts and elevators.

Generally speaking, the output of a small cashew nut processing unit ranges from 100-300kg/h.

What Is the Cost of Small Scale Cashew Nut Processing Machine?

Looking to invest in small scale cashew nut processing machines? The cost of small scale cashew nut processing machines can vary based on factors such as capacity, features, and specifications.

Generally speaking, the price of the basic configuration of the cashew production line is between 10,000-20,000 USD. The price of a small production line with a medium configuration is between 20,000 and 50,000 USD.

To determine the most cost-effective option for your needs, consider exploring reliable suppliers and manufacturers who specialize in producing high-quality small scale cashew nut processing machines.

Taizy Machinery is a professional cashew nut machinery manufacturer in China. So far, the machines have been exported to India, Cambodia, Vietnam, Cote d’Ivoire, Nigeria, Ghana and other countries.

Contact Us for the Latest Quote!

As a cashew nut processing machine manufacturer, we could provide all these cashew nut processing plant machinery. We can also give you all the professional knowledge related to the cashew nut manufacturing process. If you have any questions, please get in touch with us.