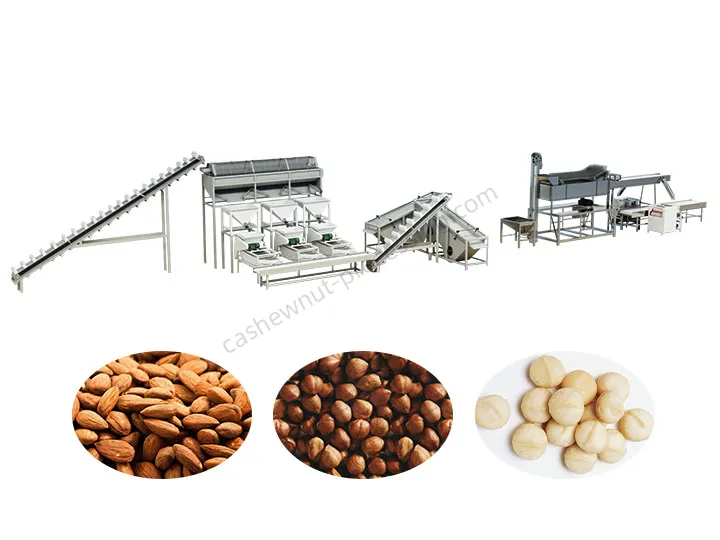

Industrial Almond Shelling Machines

| Name | Almond shelling machine |

| Raw Materials | Almond, Hazelnut, Walnut, Macadamia nut, Apricot kernel, Peach kernel, Pistachio, etc. |

| Final Products | Shelled nuts |

| Capacity | 300-1000 kg/h |

| Kernel Integrity Rate | 98% |

| Automation Level | Fully Automatic |

| Services | Techinicl support, on-site installtion, etc. |

| Warranty | One year free |

You can now ask our project managers for technical details

Stop losing money to broken kernels and slow, manual labor. Our industrial almond shelling machine line is your all-in-one solution to achieve a kernel integrity rate of up to 98% while processing 1,000-1,500 kg of raw almonds per hour. This isn’t just a machine; it’s a high-yield automated system engineered for serious producers who demand maximum output and uncompromising quality.

Why Choose Our Almond Shelling Solution?

- Maximum Profitability: With up to 98% whole kernels, you produce a higher-grade product that commands a better market price.

- Unmatched Efficiency: Our dual-control separation system uses a precise combination of vibration and air-flow to cleanly separate shells and kernels, virtually eliminating the need for manual sorting.

- Versatile Investment: While it excels as an almond shelling machine, its customizable design allows you to process other high-value nuts like Hazelnuts, Palm Nuts, and Macadamia Nuts, maximizing your ROI.

- Built for Continuous Production: All food-contact parts are food-grade Stainless Steel, mounted on a heavy-duty carbon steel frame designed for non-stop, 24/7 operation.

Technical Breakdown: The Engineering Behind the Performance

Our almond huller for sale’s superiority lies in its intelligent, multi-stage process. Each component is optimized for a specific task.

Stage 1: Precision Sizing (Rotary Drum Sizer)

The process begins by sorting raw almonds into 3-4 uniform sizes with the rotary drum sizer. This is the crucial first step to achieving a high shelling rate. The sizer uses custom-sized screen holes (e.g., flat holes for almond thickness) to ensure accuracy.

- Capacity: ~1,000 kg/h;

- Power: 2.2kw

Stage 2: Controlled Cracking (The Almond Sheller)

Sized almonds are fed into dedicated almond shelling machines. By adjusting the shelling gap for each size, we apply the perfect amount of pressure to crack the shell without damaging the kernel.

- Power: 3kw per unit;

- Shelling Components: Stainless Steel

Stage 3: Advanced Separation (Dual-Control Separator)

This is our technological core. A mix of kernels and shells enters the separator, which uses two variable-frequency motors to control vibration and air-flow independently. This creates a “fluidized bed” that lifts light shells away, while heavy kernels are cleanly discharged.

- Power: 1.5kw + 3kw (VFD);

- Sieve Decks: Stainless Steel

Stage 4: Final Grading & Inspection

Clean kernels can be passed through a final multi-layer screen to be sorted into up to 5 commercial grades, ready for packaging.

Beyond Almonds: A Multi-Nut Processing Powerhouse

The true value of these almond shell removing machines is its adaptability. By simply changing the screens and adjusting the settings, you can unlock new revenue streams:

- Hazelnut Shelling: Easily cracks and separates hazelnuts for confectionery or oil production.

- Palm Nut & Badamu Processing: The robust build handles the tougher shells of palm nuts with ease.

- Macadamia Nut Shelling: Can be configured to crack even the notoriously hard shells of macadamia nuts.

This versatility transforms a single-purpose machine into a central asset for your entire nut processing operation.

Your Partner in Nut Processing

We don’t just sell machines; we provide complete, customized solutions. Our team of engineers will work with you to design an almond shelling machine line that fits your space, meets your capacity needs, and exceeds your quality expectations.

Every producer’s needs are unique. That’s why we offer detailed consultations to ensure you get the best possible configuration. We have the right almond shelling machine for sale to elevate your business.

Ready to boost your output and quality?

Contact us today for a free consultation and a personalized quote. Let’s discuss your project and provide you with a competitive almond shelling machine price that makes sense for your business.

FAQ

What is the typical footprint of a 1-ton-per-hour line?

A standard line requires a rectangular space, but the layout is flexible. We provide detailed CAD drawings to fit the system optimally into your facility.

Can the almond shelling machine handle almonds of different moisture levels?

Yes. While optimal shelling occurs at a specific moisture content, the adjustable settings of our sheller and separator allow for effective processing of nuts with varying moisture levels.

What maintenance is required?

Maintenance is minimal. It involves regular cleaning, checking belt tension, and periodic lubrication of bearings. We provide a full maintenance schedule and support.

Do you offer installation and training?

Yes, we offer complete installation services and on-site training for your operators to ensure you can run the line at peak efficiency from day one. (Note: Please inquire about terms and conditions).