Shuliy Coated Peanut Production Line: From Raw Peanuts to Crunchy Snacks

| Name | Coated Peanut Production Line |

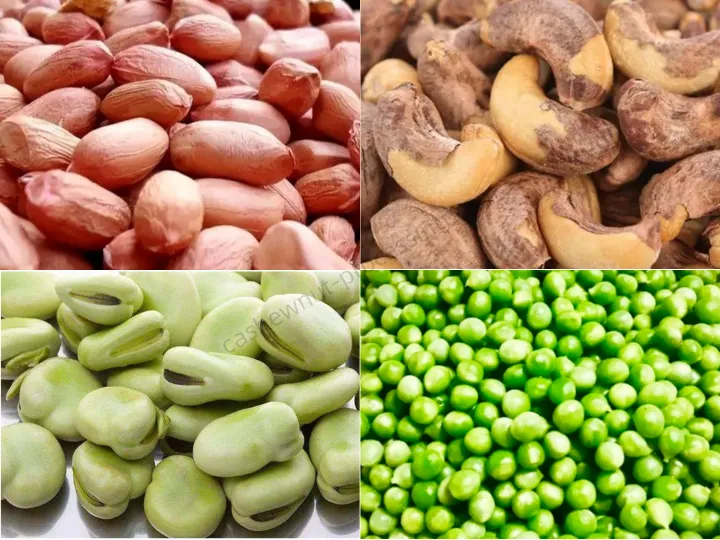

| Raw Materials | Various nuts |

| Output | Crunchy snacks |

| Specific Configuration | Customizable |

| Our services | On-site installation and operation guides |

| Warranty | One year free |

You can now ask our project managers for technical details

The Shuliy coated peanut production line is an automated system that includes roasting, dry peeling, air cooling, coating, oil spraying, and seasoning. Ideal for peanut processing factories and snack producers, it can also handle green peas, broad beans, cashews, almonds, and soybeans.

This line produces various products such as crispy coated peanuts, honey peanuts, spicy peanuts, chocolate peanuts, and salted peanuts.

Key Features of Our Coated Peanut Production Line

- High Efficiency: Fully automatic line with production capacities from 100 to 1000 kg/h.

- Quick ROI: Coated peanuts sell for 2–3× the price of raw peanuts; most customers recover costs within 6–12 months.

- Energy Saving: Smart heating and cooling system saves over 25% energy compared with traditional methods.

- Food-Grade Build: All contact parts are made of 201 stainless steel (optional 304 upgrade).

- Proven Globally: Installed successfully in Asia, Africa, the Middle East, and South America.

Production Process and Equipment Overview

Step 1: Roasting – Even Heating for Perfect Flavor

Our peanut roasting machine adopts a heat conduction and radiation principle with a rotating drum structure. It supports both electric and gas heating, and the temperature and time are adjustable. One batch takes 30–40 minutes, and each following batch takes about 20 minutes for continuous production.

| Capacity | Heating | Power | Material | Temp. Range | Time |

|---|---|---|---|---|---|

| 80–650 kg/h | Electric / Gas | 1.1–5.5 kW | 201 stainless steel (304 optional) | Ambient–300°C | 30–40 min/batch |

Key features:

- Automatic temperature control

- Uniform roasting without burning

- 201 stainless steel body (customizable to 304)

- Clean heating with no smoke contact

- Energy-saving, low maintenance

Finished Product: roasted peanuts with 3–5% moisture, strong aroma, and perfect texture for peeling.

Step 2: Dry Peeling – Soft Friction, 96% Peeling Rate

The SL Dry Peanut Peeling Machine uses multiple rubber rollers to gently remove red skins.

A built-in air fan immediately blows away the skins, keeping the workspace clean.

| Capacity | Power | Peeling Rate | Half-Seed Rate | Features |

|---|---|---|---|---|

| 200–1000 kg/h | 0.9–3.0 kW | ≥96% | ≤6% | Durable rubber rollers, stainless-steel body, dust collector system |

- Working Principle: peanuts are gently rubbed between rollers to remove skins, while air suction separates the peels.

- Output: smooth, skin-free peanuts — some in half kernels, ideal for coating.

Step 3: Coating – The Core Process of the Line

The peanut coating machine features a 30° tilted stainless-steel drum with adjustable speed, hot air heating, and an air-blowing drying system. Operators can manually add syrup, flour, or seasonings during operation.

| Drum Diameter | Capacity per Batch | Power | Main Features |

|---|---|---|---|

| 400 mm | 2–5 kg | 1.5 kW | Ideal for testing or small batches |

| 600 mm | 5–10 kg | 2.2 kW | Variable speed, hot air system |

| 1000 mm | 20–30 kg | 4.5 kW | Medium-scale production |

| 1200 mm | 30–40 kg | 5.5 kW | With heating & fast drying system |

Working Principle: Peanuts tumble and roll continuously, while flour and syrup layers alternately attach. Hot air speeds up drying, forming a uniform, glossy coating.

Step 4: Oil Spraying (Optional, Based on Budget)

After coating, customers can choose between two options:

- Budget option: Polishing machine, which completes the surface coating and shine.

- Premium option: Oil spraying machine, requiring an air compressor, for a finer and more uniform finish.

This step enhances the peanut’s flavor, gloss, and texture stability.

Step 5: Swing Oven – Second Baking & Shaping

The swing oven is used for the second-stage baking or drying process.

It applies circulating hot air heating to avoid sticking or cracking.

- Temperature: 80–120°C

- Capacity: 15–30 kg/batch

- Baking time: ≈30 minutes

Features:

- Uniform heating and color development

- Crispy texture and golden coating

- Energy-efficient continuous operation

Step 6: Cooling – Stabilizing the Structure

A 2 m³ or 3 m³ air cooling system, optionally connected to an air compressor, cools the roasted peanuts quickly to room temperature. This prevents cracking or moisture absorption, ensuring ideal coating adhesion.

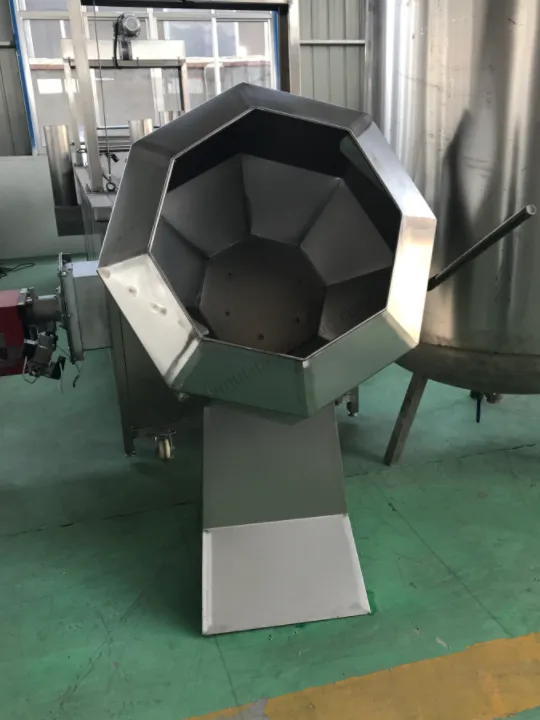

Step 7: Octagonal Seasoning Machine – Flavoring and Cooling

The octagonal seasoning machine starts from a 200 kg/h capacity.

Its special shape ensures even mixing and coating of flavor powders or liquid seasonings such as spicy, sweet, honey, or cheese.

Features:

- Adjustable rotation speed

- Automatic discharge

- Stainless steel construction

- Can connect to cooling system to maintain crispness

Step 8: Packaging Machine – Final Packing of Coated Peanuts

After cooling, the coated peanuts are automatically fed into a rotary packaging machine for weighing, filling, and sealing. The system ensures accurate dosage, stable sealing, and neat finished packages. This automatic packaging process improves efficiency, reduces labor costs, and ensures hygienic, market-ready peanut products.

Line Advantages and Finished Products

- Multipurpose system for peanuts, beans, and other nuts

- Labor saving: over 40% less manual work

- Energy saving: up to 25% reduction in power use

- Product pass rate: ≥98%

- Output peanuts are golden, crispy, smooth-surfaced, and aromatic

Profitability and Market Value

The coated peanut market is expanding rapidly worldwide. Shuliy’s production line allows you to transform raw peanuts into premium snacks with 2–3× higher selling price.

Key ROI data:

- Energy cost reduced by 25–30%

- Labor reduced by 40%

- ROI within 6–12 months

- Exported successfully to Nigeria, Egypt, Indonesia, India, Saudi Arabia, and Chile

Shuliy Provides You With

- Factory layout design and customized line configuration

- Processing formula & operation training

- After-sales installation & remote support

- Voltage and material customization for your market

Conclusion

The Shuliy Coated Peanut Production Line offers a complete solution for producing high-quality, crispy coated peanuts with stable performance and fast ROI. From roasting to flavoring, every stage is precisely controlled for consistent, export-standard quality.

Whether you’re building a new factory or upgrading an existing line, Shuliy provides reliable, energy-efficient, and cost-effective equipment solutions.

Contact the Shuliy engineering team today to get your customized quotation and production plan —

and start your profitable coated peanut business now!