Cashew Production Line Supplier in Africa.

Due to the characteristics of cashew nuts, the most primitive manual processing mode to shell cashew nuts is as follows:

Dry: dry raw cashew nuts for 2 to 3 days until the water content drops to a required level.

Cooking: steaming and dried raw cashews.

Dehulling: manually operate the shell opener, which consists of two blades. Insert the raw cashew between the blades, then press the cashew by controlling the operating lever. Each person can produce 15 to 20 kilograms per working day (8 hours), and the shelling rate of cashew nuts can reach 90%.

Roasting: dry kernels to reduce moisture content and remove the membrane adhering to seeds.

Peeling: manual removal of seed coat at an average of 9 to 10 kilograms per person per working day.

Humidity control and sterilization: control humidity before packaging. If the nuts are too dry it will shatter easily in transit. If the nuts are too wet, they may become moldy or oxidized. Sterilized nuts at high temperature before being packed.

Packaging: cashew nuts are inclined to absorb moisture, so it can be packed in vacuum or carbon dioxide filled packaging

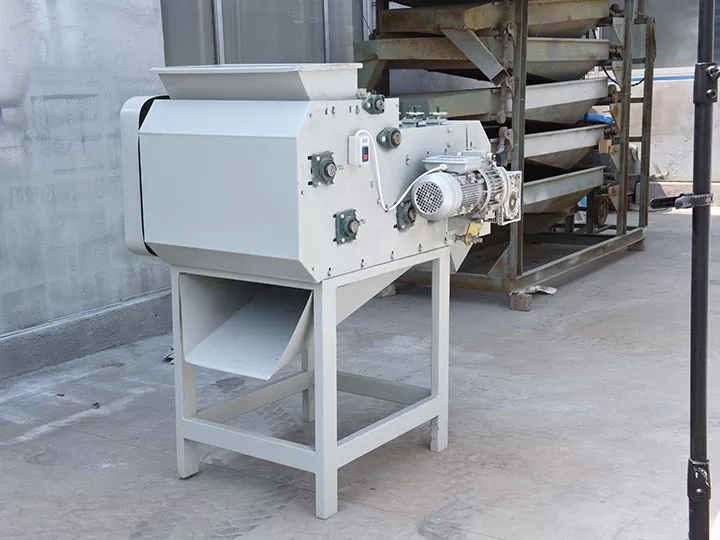

Shuliy s cashew nut sheller specialize in removing cashew nut shell. The cashew nuts should be separated into 3-5 grades manually or by a grading machine according to their width before they are hulling. With feeding action is completed automatically simple operation and high efficiency Shuliy s cashew nut sheller is the best choice for cashew nuts processing.