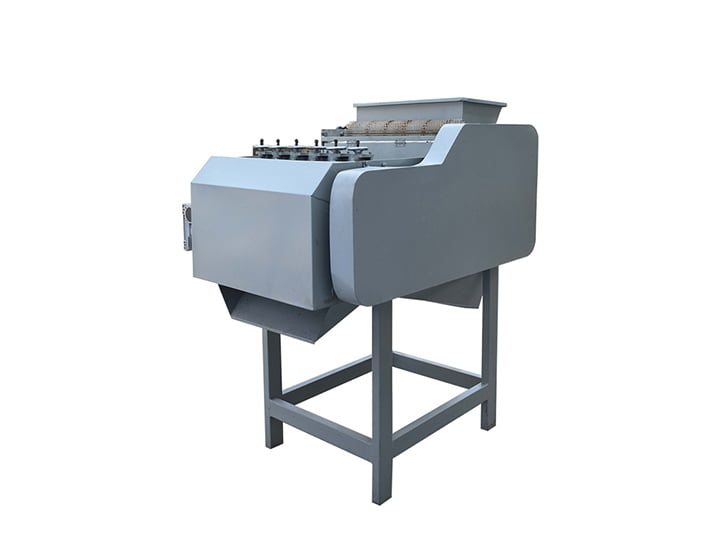

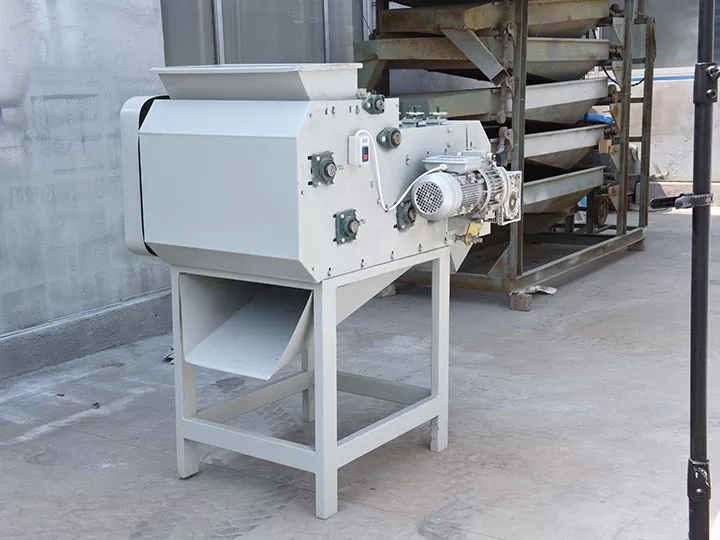

Streamline Cashew Nut Processing with an Automatic Cashew Nut Shelling Machine

Cashew nuts are a popular and nutritious snack enjoyed worldwide. However, the process of removing the outer shell from cashews can be time-consuming and labor-intensive. To address this challenge, automatic cashew nut shelling machines have emerged as a game-changer in the cashew processing industry.

In this article, we will explore the benefits, design considerations, and cost factors associated with automatic cashew shelling machines, shedding light on the efficient cashew shelling process.

The Need for Automation in Cashew Nut Shelling

Manual shelling of cashew nuts is a laborious task, requiring significant time and effort. Automatic cashew nut shelling machines offer a solution to this problem, streamlining the process and improving productivity. By automating the shelling process, these cashew nut shell remover enable higher yields, reduced labor costs, and increased overall efficiency.

Key Features and Design Considerations

Modern automatic cashew nut shelling machines are designed with several essential features to ensure optimal performance and usability. Some key considerations in the design process include:

Shell Removal Mechanism

Efficient machines employ innovative mechanisms to separate the outer shell from the cashew nut. This may involve a combination of mechanical, pneumatic, and sensor-based systems, ensuring minimal damage to the nut during the shelling process.

Sorting and Grading

Integrated sorting and grading mechanisms help separate cashew kernels based on size, quality, and appearance. This feature ensures uniformity and consistency in the final product, meeting the requirements of different market segments.

Adjustability and Flexibility

An ideal cashew nut shelling machine offers adjustable settings to accommodate varying sizes and shapes of cashew nuts. This flexibility allows processors to adapt to different cashew varieties and ensures high shelling efficiency.

Benefits of Automatic Cashew Nut Shelling Machines:

Adopting automatic cashew nut shelling machines brings numerous advantages to cashew processing businesses:

Increased Productivity

With automated shelling, the machine can process a large volume of cashew nuts in a shorter time, significantly improving productivity compared to manual methods.

Improved Quality Control

The integration of sorting and grading mechanisms enables precise quality control, ensuring consistent and superior quality cashew kernels.

Reduced Labor Costs

Automatic machines eliminate the need for extensive manual labor, resulting in cost savings and the reallocation of human resources to more value-added tasks.

Cost Considerations

The cost of a cashew nut shelling machine varies based on factors such as capacity, features, and brand reputation. While high-capacity machines with advanced features may come at a higher initial investment, they offer long-term cost savings through increased productivity and reduced labor expenses.

Conclusion

Automatic cashew nut shelling machines have revolutionized the cashew processing industry by simplifying and accelerating the shelling process. These machines bring significant benefits in terms of increased productivity, improved quality control, and reduced labor costs. When considering the purchase of a cashew nut shelling machine, it is important to evaluate design features, capacity requirements, and cost considerations to make an informed decision. Embracing automation in cashew nut processing can help businesses thrive in an increasingly competitive market, meeting the growing demand for this popular snack while optimizing operational efficiency.