Multi-functional Cashew Nut Dryer | Box Type Cashew drying machine

| Model | TZ-400 |

| Capacity(kg/h) | 400 |

| Power(kw) | 2.2 |

| Consume steam(kg/h) | 80 |

| Heat dissipating area(㎡) | 100 |

| Air volume(m3/h) | 9800 |

| Dimension(L×W×H)mm | 4380×2200×2620 |

You can now ask our project managers for technical details

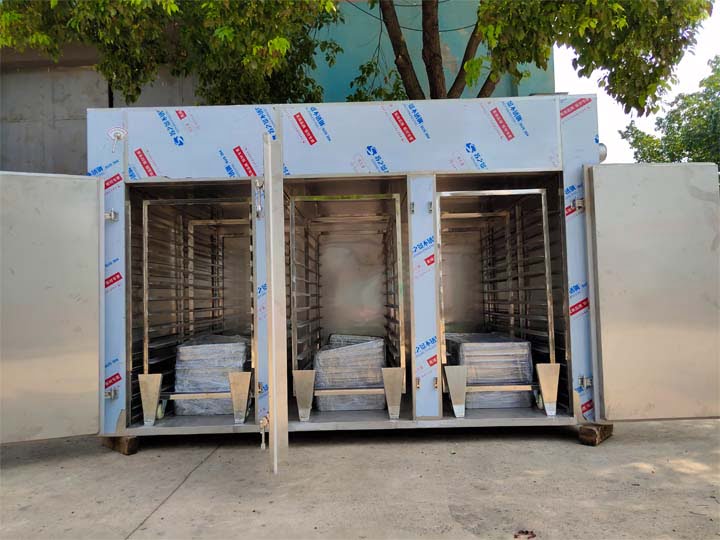

The cashew nut dryer is a tray dryer, which can dry nuts, vegetables, medicines, and other food products. It often uses in cashew nut processing plants, nut production lines, and other food processing. The stainless steel food dryer machine has a stable structure. The automatic temperature control function of the dehydration machine can maintain a constant temperature and humidity during the drying process. So the food could keep the best flavor.

Why do we need to dry cashew nuts?

The Cashew nut has a hard shell, and the shell is closely connected with its kernel. So to make the cashew shelling more efficient, we often use cashew nut cooking machine to soft the hard shells. But after the shelling process, there is still skin outside the cashew kernels. To make the cashew kernel peel faster, we use a cashew nut dryer machine to dry the skin. And then when peeling cashew kernels, it will be easier to blow off the dry skin.

Introduction of Cashew Nut Dryer

The cashew nut drying machine is also called a tray dryer. It uses electric heating to dry cashew nuts. The cashew nut dryer adopts an ultra-high temperature-resistant circulating fan. And the forced hot air heated by the electric heating tube or steam heat exchanger is circulated in the box. The nuts dryer adopts PLC intelligent control system to operate the machine, reducing manual use.

How to dry cashew nuts with Industrial Food Dryer?

The basic principle of the hot air circulation food dryer machine is to use steam or electricity as the heat energy source. The steam radiator or electric heating element generates heat. The fan is used for convective heat exchange, heat transfer to the material, and constantly replenishes fresh air to discharge moist air. Its biggest feature is that most of the hot air circulates in the box, which improves thermal efficiency and saves energy.

In a cashew dehydrator machine, cashew nut drying goes through three stages: heating, dehumidification, and cooling. The tray drying machine will run the drying process after setting the heating temperature, and dehumidification temperature. During the drying process, the inner room will maintain constant temperature and humidity.

Operation steps of food dryer machine

Close the door tightly and turn the handle of the drain valve to the “circulation” position.

Turn on the power switch of the oven controller.

Set the drying control temperature and the upper and lower limit alarm temperature according to the instructions in the “Instruction Manual of the Dryer Controller”.

Press the “fan” to start the switch; set the dehumidification time (time relay), and then turn on the heating.

Set the temperature of the instrument, press the heating switch and the oven will start to heat up.

After drying, press the fan “stop” button, and press the power “off” button.

Operation notes

- When using the cashew nut dryer for the first time, pay attention to whether the direction of each fan is correct.

- The opening angle of the drain valve determines according to the moisture content of the material.

- Read the instruction manual of the instrument in detail before using the machine.

- The door sealing strip is aging and invalid and should be replaced in time.

- The surface of the cashew nut dryer should avoid damage caused by the collision of hard objects and heavy objects.

- Drying flammable and explosive materials is strictly prohibited.

- The maximum working pressure of the steam radiator is 0.8Mpa, and the use of overpressure is prohibited.

- If the operating temperature of the oven is required to reach 120~140℃, that is, the steam pressure should be in the range of 0.4~0.8 Mpa. If the temperature in the box is required to reach 80~120℃, that is, the steam pressure should be 0.2~0.4Mpa.

- For newly installed and reused steam-heated ovens after long-term decommissioning, be sure to close the front and rear stop valves of the solenoid valve, open the bypass valve, and flush the dirt and sewage in the pipeline with steam to prevent the solenoid valve from being blocked and malfunctioning.

- The steam inlet valve should be opened slowly, and the steam filter should be cleaned regularly

- After one year of use, the local testing department should test the various mechanical and safety requirements of this equipment, and decide to continue using it after the test results reach the standard. If the test fails to meet the indicators, stop using it.

Cashew Nut Dryer Application

The tray dryer is widely used in drying raw materials or products such as pharmaceutical, chemical, nut, agricultural, and sideline products. It is also suitable for drying fruits, agricultural and subsidiary dehydrated vegetables, feedstuffs, condiments, clothing, food, and other industries.

Highlights of Cashew Nut Drying Machine

- The nuts dryer body adopts a fully enclosed structure, circulating in the hot air box, reasonably discharging hot and humid air, and replenishing fresh air.

- The heat transfer is enhanced, the evaporation rate of water is increased and the drying time is shortened.

- The whole cashew nut dryer has low noise, balanced operation, automatic temperature control, and convenient installation and maintenance.

- It has a wide range of applications and can dry all kinds of materials.

- Cashew nut dryer is equipped with an automatic temperature control system to control temperature accurately. An adjustable air distribution board is arranged in the box, and the temperature inside the box is even.

- The use of low noise and energy-saving built-in circulating fan, the operation balance, greatly reduced the noise and heat loss of the equipment, air inlet with air filter, marking the wetting device.

Box Type Cashew Nut Dryer Parameters

| Model | Capacity(kg/h) | Power(kw) | Consume steam(kg/h) | Heat dissipating area(㎡) | Air volume(m3/h) | Dimension(L×W×H)mm |

| TZ-25 | 25 | 0.45 | 5 | 5 | 3400 | 1550×1000×2044 |

| TZ-50 | 50 | 0.45 | 10 | 10 | 3400 | 1400×1200×2000 |

| TZ-100 | 100 | 1.1 | 20 | 20 | 1400 | 2430×1200×2375 |

| TZ-200 | 200 | 1.1 | 40 | 40 | 5200 | 2430×2200×2433 |

| TZ-300 | 300 | 2.2 | 60 | 80 | 9800 | 3430×2200×2620 |

| TZ-400 | 400 | 2.2 | 80 | 100 | 9800 | 4380×2200×2620 |

| TZ-D100 | 100 | 0.45 | 18 | 20 | 3450 | 2300×1200×2000 |

| TZ-D200 | 200 | 0.9 | 36 | 40 | 6900 | 2300×2200×2000 |

| TZ-D300 | 300 | 1.35 | 54 | 80 | 10350 | 2300×3220×2290 |

| TZ-D400 | 400 | 1.8 | 72 | 100 | 13800 | 4460×2200×2290 |

| TZ-X120 | 120 | 0.9 | 20 | 25 | 6900 | 1460×2160×2250 |

Installation of Cashew Nut Dryer Machine

The user lays the steam pipeline and power cord outside the box food dryer machine as required.

Connect the power cord and firmly ground the outer wall of the device. Connect the vent pipe to the outdoor.

- The multi-layer cashew drying machine should install on level ground.

- The power input of the equipment is three phase wires and one neutral wire. The total power is 12.73KW, the voltage is 380V, and the frequency is 50Hz.

- The outer wall of the cashew nut dryer machine should be firmly grounded.

- Adjust the opening of the air guide plates on both sides of the box to make the temperature in the box even. According to experience, the opening of the upper section of the air deflector on the side of the oven fan (circulating air negative pressure) is relatively small, and the opening of the lower section is relatively large. The opening of the wind deflector on the other side (positive pressure of circulating wind) is the opposite, with the upper section being larger and the lower section being smaller. If the temperature of a certain place is found to be low after the oven heating test, the air deflector near the place should be opened properly; on the contrary, when the temperature is high, it should be properly closed.

- After the equipment is installed, close the electrical switch and check whether the circuit is connected (the indicator light of the controller is on).

- Press the “Power On” and “Fan Start” buttons on the controller in turn to start the fan. And check whether the direction of the fan is consistent with the direction indicated by the arrow and whether there is any abnormal sound.

Precautions before using box cashew nut drying machine

- Purchase our company’s CT, CT-C, series of hot-air circulation ovens (whether steam heating or electric heating, hereinafter referred to as ovens), if our company’s ovens do not indicate “Allow flammable and explosive materials to be used together”, flammable is strictly prohibited Explosive substances enter the above-mentioned oven.

- For the cashew nut dryer in use, clean the inside of the oven, including the ventilation system and heater regularly. And clean the dust accumulated on the surface to prevent its carbonization and ignition.

- According to the national testing rules for measuring instruments, the instruments (primary and secondary instruments), automatic control actuators, electrical equipment and circuits used in our company’s ovens are regularly inspected and measured to ensure their safety, reliability, and accuracy.

- For all ovens in use, clean and replace the air inlet and outlet filters regularly.

- When using the oven, it is strictly forbidden to be unattended on site. Once there was an abnormal phenomenon, immediately cut off the power supply and allow it to cool to room temperature before opening the door.

- When the operator leaves the site after getting off work, the main power supply of the oven must be cut off.

- The cashew nut dryer that has not been used for a long time can be put into use after re-executing items 2, 3, and 4 above when it is used again.