Cashew Roasting Machine | Swing-Coated Cashew Nut Roaster Machine

Cashew Nut Roaster Machine | Nut Roasting Machine

Taizy cashew roasting machine can effectively reduce the moisture content of cashews to 2%-3%. At Taizy Machinery, we have two heating methods for customers to choose from: electric heating and gas heating.

With advanced temperature control and automated processes, it ensures that each batch of nuts is roasted to perfection.

Whether you operate a small-scale cashew business or a large industrial operation, investing in a cashew roaster machine can significantly boost your productivity

The video of the drum-type cashew roasting machine

Application of cashew nut roasting machine

This cashew roasting machine is mainly used in the food processing industry. You can use it to roast cashew nuts, almonds, peanuts, hazelnuts, chestnuts, pine nuts, and others.

The machine can also roast soybeans, chickpeas, coffee beans, cocoa beans, and other legumes. In addition, you can also use this machine to roast pumpkin seeds, sunflower seeds, melon seeds, sesame seeds, and other seed materials.

Types of cashew roasting machines

The two types of cashew nut roasting machines commonly sold on the market are drum type and swing type. As a professional cashew nut machinery manufacturer, we can provide both types of cashew nut roasting equipment.

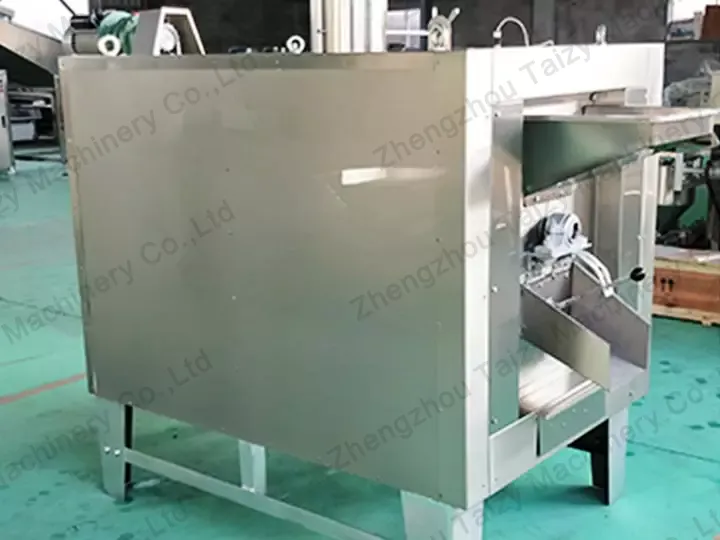

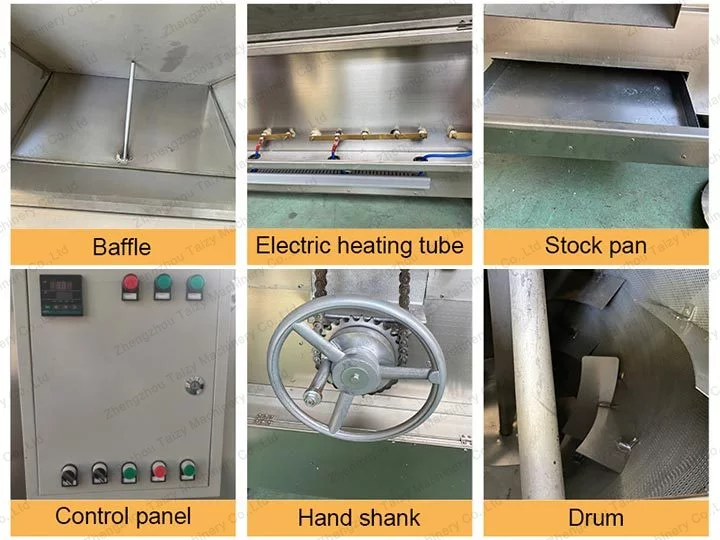

Drum cashew roasting machine

The cashew nut roaster machine adopts a rotary drum and applies the principles of heat conduction and heat radiation. It has a cheap production cost, and the to-be-baked object is not in contact with the fire during roasting.

Why choose this drum cashew nut roaster machine?

It has been proved by many cashew nut production factories that the machine has the advantages of convenient use, high efficiency, energy-saving, and durability. The roasted products are of good quality, clean and hygienic, with pure taste, meeting export standards.

Drum cashew roasting machine technical data

| Model | Size(mm) | Capacity(kg/h) | Motor power(kw) | Electric heating(kw) | Gas heating(kg) |

| MHK-1 | 3000*1200*1700 | 80-120 | 1.1 | 18 | 0.9-2 |

| MHK-2 | 3000*2200*1700 | 180-250 | 2.2 | 35 | 1.8-3 |

| MHK-3 | 3000*3300*1700 | 280-350 | 3.3 | 45 | 2.6-4 |

| MHK-4 | 3000*4400*1700 | 380-450 | 4.4 | 60 | 4-6 |

| MHK-5 | 3000*5500*1700 | 500-650 | 5.5 | 75 | 6-8 |

The capacity range of this drum cashew roasting machine is 80-650kg/h. Therefore, you can use this machine in small, medium, and large cashew processing plants.

In addition to the above data, do you want to know more about this machine? Welcome to contact us through the contact information in the lower right corner.

Swing cashew nut roaster machine for coated cashew

The swing cashew nut oven is composed of an inner stove, roasting stray, movable brackets, etc. It adopts the working principle of heat transmission and thermal radiation.

The machine is equipped with a flat tray, which is driven by the rotating plate through two movable brackets that can rotate horizontally and continuously.

The removable tray carries the semi-finished coated cashews, ensuring that each coated cashew is evenly heated. The coated cashews are constantly rolled during the roasting process to achieve the ideal roasting effect.

Why choose a swing-type cashew roaster?

Coated cashews are sticky, so the general roasting method cannot achieve uniform roasting. The general roasting method can only roast two sides of the coated cashews at most. Our company’s swing cashew roaster can evenly roast all sides of the cashews.

Swing cashew roasting machine parameters

| Capacity | 80-100kg/h |

| Size | 2.2*2*1.4m |

| Voltage | 380v 50hz |

| Power | 25kw |

| Temperature | 180-220℃ |

The output of the swing cashew roasting machine is 80-100kg/h. The size is 2.2x2x1.4m. It is suitable for small and medium cashew processing plants.

Advantages of Taizy cashew roasting machine

- High-quality materials. Both machines are made of stainless steel, which is sturdy and durable.

- Wide range of applications. Cashew nut roasting machines can also roast beans, grains, seeds, and nuts.

- Less heat loss. The heat insulation cotton design inside the machine can reduce heat loss during the operation of the machine.

- Simple operation. The button operation allows workers to operate this machine easily.

What is the price of a cashew nut roasting machine?

The price of a cashew nut roasting machine can vary widely depending on the machine’s model, capacity, features, and brand.

Entry-level models, suitable for small-scale operations, can start at around $1,500, while high-capacity, industrial-grade machines can cost upwards of $10,000.

Factors influencing the price include the type of heating (electric or gas), automation level, and additional features like temperature control and uniform roasting capabilities.

If you want to know the price of a cashew nut roasting machine, please feel free to contact us.

Working process of cashew roasting machine

- Preheat the machine: turn on the heating system and adjust the temperature to the required roasting temperature.

- Feeding: put the cashews into the cashew nut roaster machine through the feeding port.

- Roasting: start the rotating system, the cashews will roll evenly in the drum and heat for a predetermined time.

- Discharging: after roasting, the automatic discharging system will discharge the baked cashews from the discharging port.

Precautions for using the kaju roasting machine

- Before starting the kaju roasting machine, check whether the electric control system of the rotating cage is normal, whether the bolts of the rotating part are loose, and whether the thermocouple pointer or the digital display is flexible.

- Check gear oil and grease in the reducer of the rotary cage and the bearings at both end regularly to prevent damage due to lack of oil.

- Check the bottom of the rotating cage to remove accumulated ash and other debris in the machine to prevent smoke and fire from polluting the roasted food.