Máquina Industrial de Picagem de Amendoim

| Nome | Máquina de corte de amendoim |

| Tipos de Máquinas | Lâmina Reta & Cortador de Rolo |

| Faixa de Capacidade | 200 - 500 kg/h |

| Materiais Processados | Amendoins, Amêndoas, Nozes, Castanhas, etc. |

| Níveis de Classificação | Até 4 categorias distintas |

| Métodos de Controle de Tamanho | Velocidade da Correia Transportadora / Ajuste do Espaçamento do Rolo |

| Garantia | Um ano de garantia gratuita |

Agora você pode pedir detalhes técnicos aos nossos gerentes de projeto

Tamanho de partícula inconsistente pode arruinar um produto. Para os processadores de alimentos, alcançar o corte perfeito para amendoins, amêndoas ou nozes não é apenas um detalhe — é crítico para a qualidade. A Taizy Machinery entende este desafio. Não oferecemos uma solução única para todos; em vez disso, fornecemos uma gama diversificada de máquinas industriais de corte de amendoim, cada uma projetada para um propósito específico. Vamos encontrar a ideal para si.

A Nossa Linha de Cortadores de Amendoim: Lâmina Reta vs. Cortador de Rolo

Na Taizy, os nossos cortadores de nozes dividem-se em duas categorias principais com base na tecnologia de corte: a versátil Série de Cortadores de Lâmina Reta e o eficiente Cortador de Rolo.

A Máquina de Corte de Amendoim com Lâmina Reta: Para Classificação de Precisão

Nossas máquinas de corte de amendoim com lâmina reta são o padrão da indústria para produzir partículas múltiplas, uniformemente classificadas, em uma única passagem.

Como Funciona: Todos os modelos de lâmina reta partilham um princípio central. As nozes são alimentadas numa correia transportadora e passadas sob um conjunto de lâminas reciprocantes verticais. A velocidade da lâmina é constante, mas pode controlar-se precisamente o tamanho final das partículas ajustando a velocidade da correia — uma correia mais lenta significa mais cortes e partículas mais finas. Após o corte, um sistema de tela vibratória assume para classificar as partículas.

Oferecemos várias configurações para atender às suas necessidades específicas de classificação:

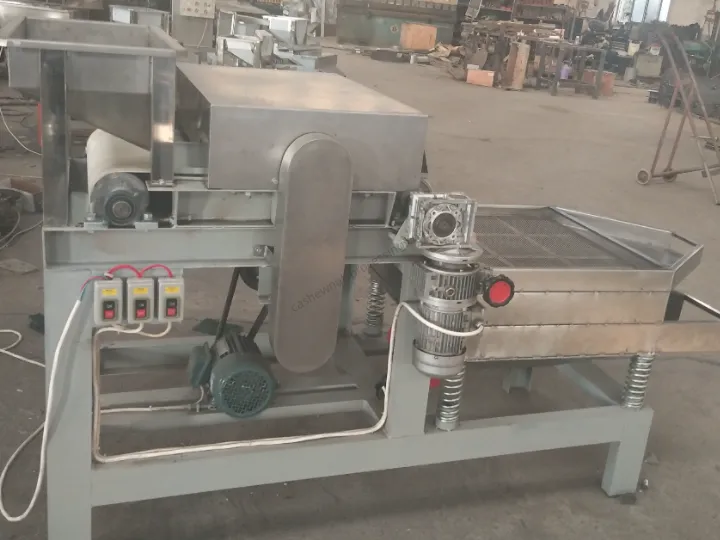

Modelo 1: O Cortador de Tela Única de Alta Resistência

Este é o nosso modelo de potência, construído para durabilidade e facilidade de uso em ambientes de produção exigentes.

- Sistema de Classificação Único: Apresenta uma tela de uma única camada, inteligentemente dividida em três zonas distintas, cada uma com uma malha de tamanho diferente. Isto permite que a máquina separe as nozes picadas em quatro categorias diferentes simultaneamente.

- Fácil de Limpar: O design de tela única torna a limpeza e manutenção simples, minimizando o tempo de paragem.

- Construído para Confiabilidade: O armário de controlo elétrico é separado do corpo principal da máquina. Esta característica de design crucial protege os eletrônicos sensíveis de vibrações, prolongando significativamente a vida útil da máquina.

Melhor para: Produtores de alto volume que precisam de várias categorias uniformes de produto e valorizam robustez e manutenção simples.

Modelo 2: A Máquina de Corte de Amendoim de Múltiplas Camadas de Precisão

Este modelo de aço inoxidável é projetado para máxima precisão de classificação e é perfeito para empresas com requisitos complexos de produto.

- Classificação Avançada de Múltiplas Camadas: Esta máquina está equipada com uma tela vibratória de três camadas. Cada camada tem um tamanho de malha diferente, permitindo uma classificação altamente precisa das nozes picadas em múltiplas categorias com precisão excecional.

- Design Higiênico: Frequentemente construído com aço inoxidável completo, está pronto para os ambientes mais rigorosos de segurança alimentar.

Melhor para: Processadores de alimentos que requerem o mais alto nível de precisão na classificação para produzir várias partículas distintas e altamente uniformes para produtos premium.

Também Oferecemos Soluções Personalizadas! Precisa de uma tela de duas camadas ou de outra configuração específica? Podemos personalizar os nossos cortadores de lâmina reta para combinar perfeitamente com a sua linha de produção.

A Máquina de Corte de Rolo e Faca

A máquina de corte de amendoim com cortador de rolo oferece uma abordagem diferente para o corte de nozes, focando na simplicidade e controlo direto.

Como Funciona: Em vez de lâminas verticais, esta máquina usa um par de cortadores de rolo horizontais para cortar as nozes. A sua principal vantagem reside na facilidade de ajuste do tamanho.

- Controlo Direto de Tamanho: Pode alterar diretamente o tamanho final das partículas ajustando a folga entre os dois rolos. Uma folga menor produz partículas mais finas. Isto fornece uma forma direta de definir o tamanho de corte primário desejado.

- Eficiente e Moderna: Este design mais recente é otimizado para reduzir o desperdício de material e o acúmulo de óleo durante a operação, garantindo um processo mais limpo.

- Saída em Múltiplos Estágios: Como os nossos outros modelos, está equipado com um sistema de tela vibratória (tipicamente de duas camadas) para classificar o material picado em três categorias diferentes.

Melhor para: Empresas que procuram uma solução económica e fácil de operar. Enquanto os modelos de lâmina reta destacam-se por criar categorias mais uniformes, o cortador de rolo é excelente para aplicações onde o tamanho de corte principal é o objetivo principal, e uma variação de textura mais natural é aceitável ou até desejada.

De Olho: Qual Cortador de Nozes é o Ideal para Si?

| Recurso | Lâmina Reta de Alta Resistência | Lâmina Reta de Precisão | Cortador de Rolo e Faca |

|---|---|---|---|

| Método de Corte | Lâminas Reciprocantes | Lâminas Reciprocantes | Cortadores de Rolo |

| Controle de Tamanho Primário | Velocidade da Correia Transportadora | Velocidade da Correia Transportadora | Ajuste do Espaçamento do Rolo |

| Sistema de Classificação | Tela Única (3 Zonas) | Tela de Múltiplas Camadas (3 Camadas) | Tela de Múltiplas Camadas (2 Camadas) |

| Número de Categorias | Até 4 | Até 4 (Alta Precisão) | Vantagem Principal |

| Durabilidade & Limpeza Fácil | Máxima Precisão na Classificação | Operação Simples & Baixo Desperdício | Independentemente do modelo que escolher, todas as máquinas Taizy podem ser personalizadas com aço inoxidável de grau alimentar 304 ou 316. Estamos comprometidos em fornecer-lhe não apenas uma máquina, mas uma solução completa que melhora a qualidade do seu produto e aumenta a sua eficiência. |

O Seu Parceiro em Processamento de Alimentos

Contacte a nossa equipa de especialistas hoje para uma consulta gratuita e uma cotação personalizada!

Pronto para encontrar a máquina de corte perfeita para os seus amendoins, amêndoas ou castanhas?

Máquina Industrial de Corte de Amendoim 1