High-Efficiency Peanut Brittle Production Line

| 姓名 | Peanut brittle production line |

| 容量 | 300-400 kg/h (Customizable) |

| Key Materials | Food-Grade Stainless Steel |

| 电压 | Customized to your country's standard |

| Configuration | Fully customizable to fit your needs |

您现在可以向我们的项目经理询问技术细节

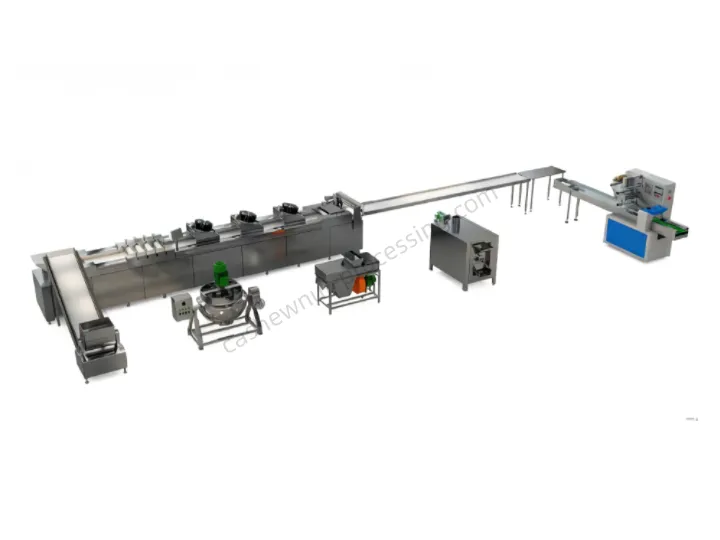

Shuliy Machinery’s peanut brittle production line is a fully automated solution engineered for the efficient, large-scale production of high-quality peanut brittle, nut bars, and other confectionery snacks. This integrated system is designed to boost your output, ensure product consistency, and reduce labor costs, making it the ideal investment for modern food processing enterprises.

This article details a representative 300-400kg/h line. Please note, we specialize in customizing every solution to meet your specific production goals and market needs.

Key Advantages of Our Production Line

- High Automation: Significantly reduces manual labor, minimizes operational errors, and lowers long-term production costs.

- Consistent Quality: The automated process ensures every bar has a uniform thickness, size, and taste for a premium final product.

- Food-Grade Durability: Key components are constructed from high-quality stainless steel, ensuring longevity and compliance with international food safety standards.

- Production Versatility: This line is not limited to one product. Its adaptable design allows for a diverse range of snack bar production.

Versatile Raw Materials & Finished Products

While perfectly suited for classic peanut brittle, the true strength of this peanut brittle production line lies in its versatility. You can easily adapt your production to meet changing market trends.

Applicable Raw Materials:

- Nuts: Peanuts, almonds, walnuts, cashews, hazelnuts.

- Seeds: Sesame seeds, sunflower seeds, pumpkin seeds.

- Grains & Cereals: Puffed rice, oats, granola, crisped cereals.

- Fruits: Dried fruits like raisins or cranberries can be mixed in.

- Binder: Sugar, syrup, honey, or chocolate.

Finished Product Applications:

- Peanut Brittle (Peanut Chikki)

- Sesame Candy Bars

- Almond Brittle & Mixed Nut Bars

- Granola Bars & Cereal Bars

- Energy Bars

Our Automated Workflow: From Ingredient to Final Product

1. Roasting Machine

This machine uses a consistent, electrically heated rotating drum to ensure every nut is roasted uniformly, unlocking maximum flavor and a perfect aroma.

- Capacity: 80-120 kg/h

- Motor Power: 1.1kw

- Heating Power: 23kw

2. Peanut Peeling Machine

Utilizing a gentle friction roller system, this peeler efficiently removes the skins from roasted peanuts with a high purity rate, ensuring a clean appearance for the final product without damaging the nuts.

- Capacity: 200-300 kg/h

- Purity Rate: 98%

3. Sugar Boiled Pot

This jacketed, 304 stainless steel pot uses stable electric heating and an integrated stirrer to produce a perfectly consistent syrup binder, preventing scorching and ensuring uniform quality.

- Capacity: 200L

- Power: 18kw

- Features: Tilting body for easy discharge, Food-grade 304 SS

4. Material Mixing Machine

Designed for perfect blending, this machine features a heated, insulated pot that maintains the syrup’s temperature while its powerful arm thoroughly coats every ingredient for a homogenous mixture.

- Capacity: 15 kg/batch

- Power: 1.1kw

- Feature: Double-deck pot for heat preservation

5. Forming and Cutting Machine

This is the core of the line. It uses a series of adjustable pressure rollers to flatten the mixture into a uniform slab, then employs a set of precise longitudinal and latitudinal blades to cut it into your desired product dimensions.

- Capacity: 300-400 kg/h

- Power: 2.5kw

- Belt Width: 560 mm (adjustable forming thickness)

6. Cooling Conveyor

The freshly cut bars are transferred onto this conveyor. The extended travel time allows the products to cool and harden naturally, giving them the perfect crisp texture before packaging.

- Power: 0.37kw

- Dimensions: 5000*1000*800 mm (customizable length)

7. Automatic Packing Machine

This machine provides the final professional touch, automatically wrapping and sealing each bar. It can be equipped with a coding function to print dates or batch numbers for full traceability.

- Power: 1.92kw

- Max Film Width: 250 mm

- Function: Wrapping, Sealing, and optional Coding

Peanut Brittle Production Line Specifications

| 特征 | Specification |

|---|---|

| Line Capacity | 300-400 kg/h (Example Configuration) |

| Finished Product Size | Length & Width are adjustable via the cutting machine |

| 电压 | Customized to match your country’s standard (e.g., 220V/380V, 50Hz/60Hz) |

| Main Materials | Food-contact parts are made of high-quality Stainless Steel |

| Layout & Configuration | Fully customizable; machines can be added or removed to fit your needs |

| Delivery Time | 10-15 working days after receiving payment |

| Quality Guarantee | 12 months for all malfunctions caused by machine-self and quality |

| After-Sales Service | Lifetime technical support, operation videos, and professional advice |

Contact Us for Your Custom Solution

Ready to automate and scale your confectionery business? Contact us today to discuss your project requirements. We will provide a detailed, no-obligation quote for a peanut brittle production line designed to help you succeed.